Products

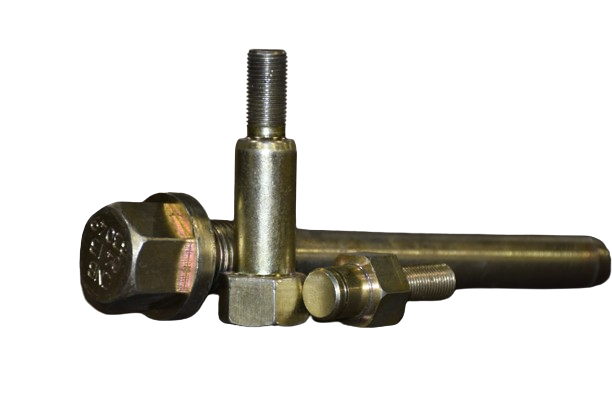

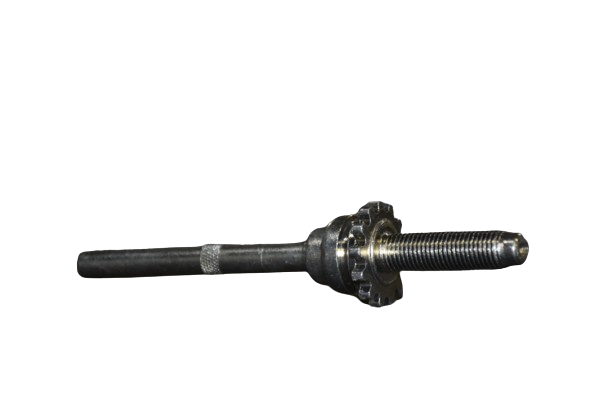

Tru-Fit uses precision machining and cold forming to create customized construction fasteners that meet the exact specifications of your job.

We offer a variety of materials and options, including multi-station forming equipment that allows us to offer products ranging from 5/32″ to 1 3/8″ diameter, with some lengths exceeding 10″. In addition to manufacturing production runs of virtually any quantity, you can look to Tru-Fit Products to engineer cost effective designs that meet your requirements.

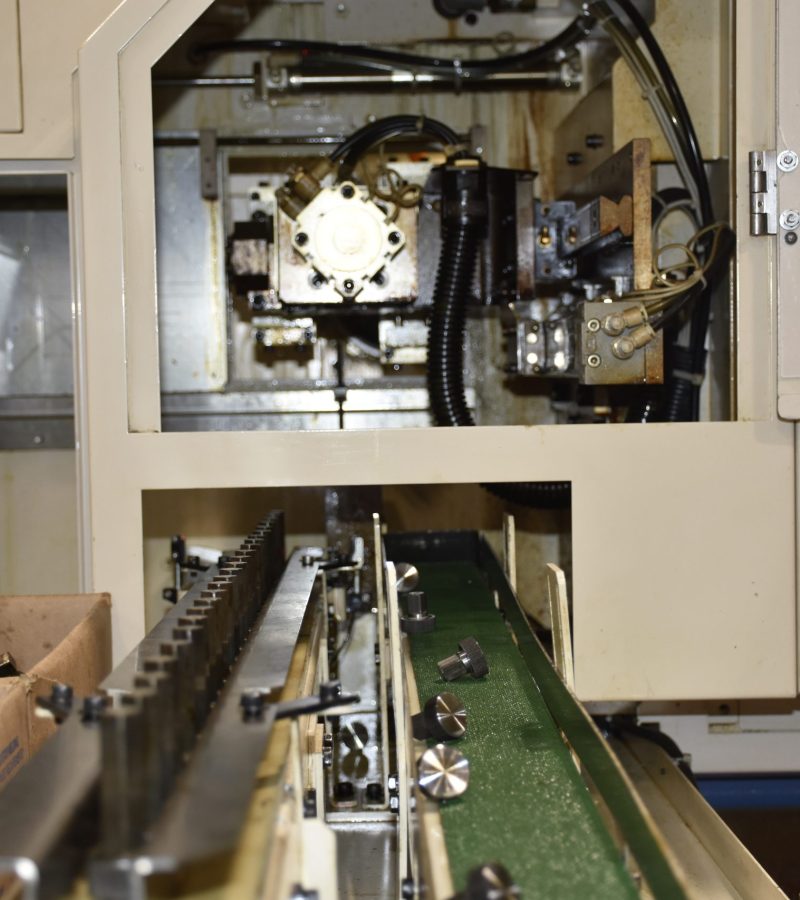

Cold Forming

When cold forming construction fasteners, we start with a coil of rod. The header draws the rod into wire and shears it off to a precise length so that the cubic volume of wire is equal to the volume of the finished part after forming. A hammer then rams the wire piece into the first station die to produce a different shape, ejects it, grabs it, and transfers it to the next station. This process is repeated in each successive station, shaping the part until it has been formed into its final, blank configuration.

Because cold forming produces the product in the final form, there is little or no secondary machining required, greatly reducing wasted material.

Examples are:

T-bolts

Eye bolts

Seat Track Bolts

Penta Bolts

H-Bolts

Injection Stud

12 Point Bolts

Double Ended Stud

From initial design to final assembly, we provide a range of services that means your fasteners are of the highest quality and that your product is delivered on time and on budget.

Our full range of services include:

Engineering

Our engineering staff is not only responsible for researching and developing new techniques in cold-heading special fasteners, but also for providing technical direction to meet the requirements of cost reduction in today’s marketplace.

Before we begin, prints are drawn by our expert staff and submitted to you ensuring a quality product, which satisfies your requirements.

Heat Treating

Our heat treating options feature the latest technology in process control systems. This system closely monitors and controls atmospheres and furnace cycles, resulting in increased productivity and quality for heat-treated fasteners.

With both batch and continuous furnace capabilities, we have the versatility and experience to meet our customers’ heat-treating needs.

Electroplating

We take pride in knowing that the first thing you will notice is the quality finish of our product. Rest assured that corrosion resistance and uniformity of appearance are of equal importance to us.

Our in-house lab continually monitors and certifies all of our plating operations.

A programmable controller has provided a tighter control of our coating process, resulting in better uniformity, appearance, and overall quality of our coating.

Rainbows of colors are available for easy part identification applications. Ask your Tru-Fit sales representative for details.

Product Assembly

The ability to provide a completely assembled product to our customers allows a reduction in both lead time and cost. We welcome inquires on producing an assembly that contains specialty fasteners.

Secondary Operations

In many of our secondary operations, we are designing and building automated processing equipment. Where feasible, we are utilizing robotics and programmable control systems.

The ability to perform numerous types of secondary operations allows most part configurations to be made in house.

Custom CNC and NC machining is available for special requirements and close tolerances;

- drilling

- milling

- tapping

- knurling

- turning

- bending

- thread rolling

Tru-Weld Has it in stock!

Don’t see what you are looking for? Interested in Weld Studs & Stud Welding Equipment? Please visit Tru-Weld Stud Welding