Many types of ferrous and non-ferrous material can be cold-headed.

Tru-Fit purchases all materials directly from the steel mill and follows proper steel preparation techniques to guarantee a quality finished product.

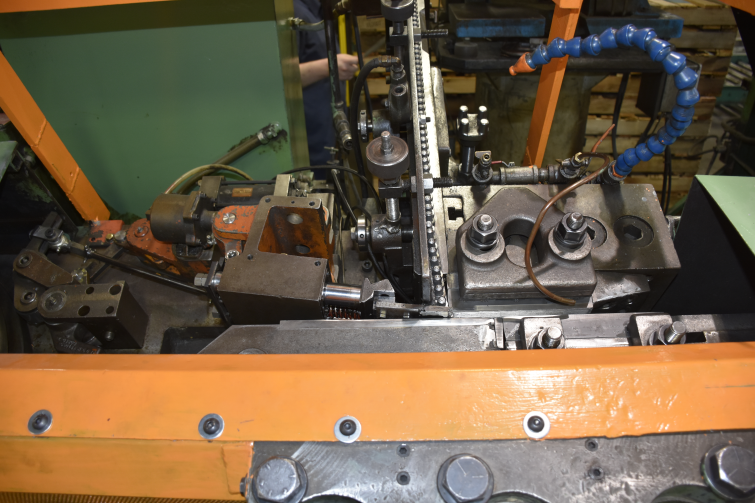

Custom tools and new techniques provide Tru-Fit the ability to manufacture parts in many configurations. With the installation of CNC machining equipment, we have increased our tool making capabilities to further ensure quality cold-formed parts.

Don’t see what you are looking for? Interested in Weld Studs & Stud Welding Equipment? Please visit Tru-Weld Stud Welding

© All Rights Reserved.